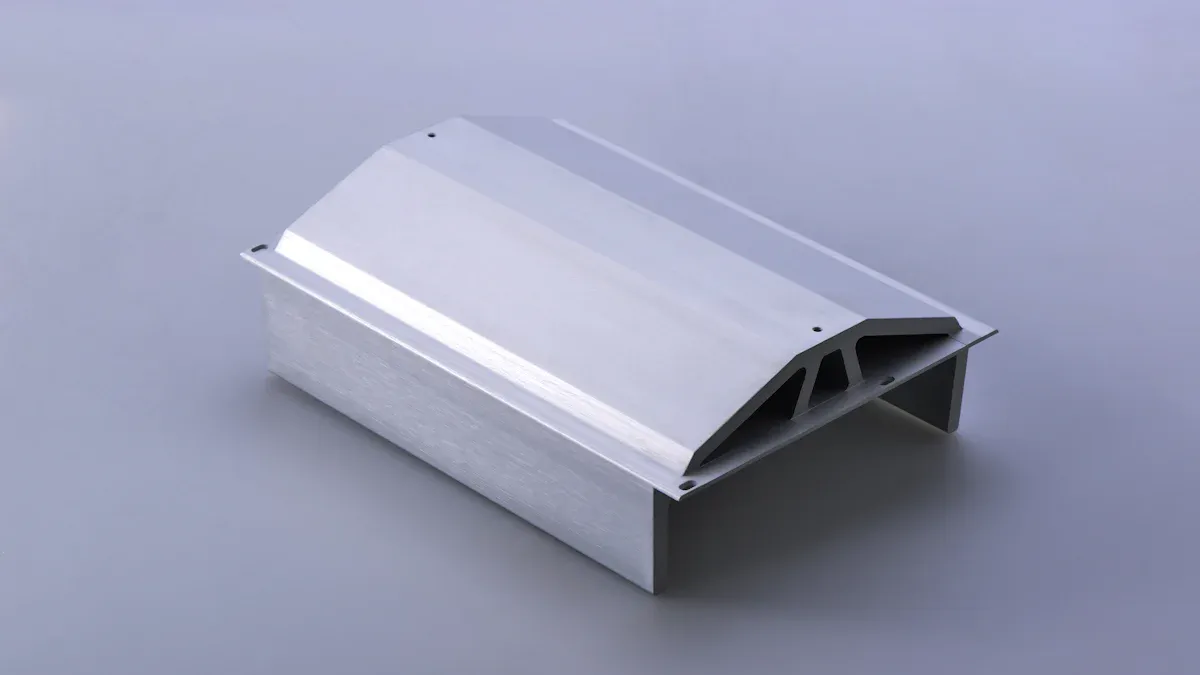

Abathengi be-OEM baya ngokuya bekhetha amaphrofayili e-aluminium extrusion ngenxa yezinzuzo zabo ezihlukile kumathuluzi wangokwezifiso namaphrojekthi womjovo wepulasitiki. Isidingo esikhulayo sezinto ezingasindi nezihlala isikhathi eside sishayela lo mkhuba, ikakhulukazi ezinhlelweni zokusebenza ezifana nezinsimbi zesango lokugezela kanyeizibambo yokugezela ifenisha idonsa. Izinhlaka ezilawulayo ziqinisa umkhawulo wokukhipha isisi, okuphoqa ukuthi usebenzise izinto ezisetshenziswayo eco-friendly. Amaphrofayili e-aluminium extrusion anikeza ukuguquguquka nokusebenza kahle kwezindleko ezihlangabezana nezidingo zesimanje zokukhiqiza.

Okuthathwayo Okubalulekile

- Amaphrofayili e-aluminium extrusionangasindi kodwa aqinile, okuwenza alungele ukusetshenziswa ezimbonini ezifana nezezimoto kanye ne-aerospace.

- Lawa maphrofayiliukumelana nokugqwala kangconokunensimbi, ukunciphisa izindleko zokunakekela kanye nokwelula isikhathi sokuphila sezingxenye.

- Ama-Aluminium extrusions anikeza ukuguquguquka komklamo, okuvumela umumo oyinkimbinkimbi nezici ezithuthukisa ukusebenza kahle nobuhle.

Izinzuzo ze-Aluminium Extrusion Profiles

Ilula futhi Iqinile

Amaphrofayili e-Aluminium extrusion anikeza isilinganiso esimangalisayo samandla nesisindo, okuwenza alungele izinhlelo zokusebenza ezihlukahlukene. Nakuba insimbi inamandla ngokobuchwepheshe, isisindo esilula se-aluminium sivumela ukuphatha nokufaka kalula. Lesi sici sizuzisa kakhulu ezimbonini ezifana nezezimoto kanye ne-aerospace, lapho ukwehlisa isisindo kubalulekile. Ungakwazi ukusebenzisa izakhiwo ezifanelekayo ze-aluminium ukuze uthuthukise imiklamo yakho ngaphandle kokuphazamisa ubuqotho besakhiwo.

- Izinzuzo Eziyinhloko:

- Ama-Aluminium extrusions alula kunensimbi, okwenza kube lula ukuthutha nokuhlanganisa.

- Amandla e-aluminium esewonke, lapho ifaka isisindo sayo esilula, ayenza ibe ukukhetha okuncintisana ezinhlelweni eziningi ze-OEM.

- Izakhiwo zalezi zinto zizuzisa kakhulu emikhakheni lapho ukunciphisa isisindo kubalulekile.

Ukumelana Nokugqwala

Esinye sezici ezivelele zamaphrofayili e-aluminium extrusion yikhono lawo elimangalisayo lokumelana nokugqwala. Lapho ivezwe emoyeni, i-aluminium yenza ungqimba lwe-oxide oluvikelayo oluyivikela ekulimaleni kwemvelo. Le ndlela yokuzivikela yemvelo iphakeme kuneyensimbi, ejwayele ukugqwala futhi idinga izinyathelo zokuzivikela ezengeziwe.

- Amaphuzu Avelele Wokumelana Nokugqwala:

- I-Aluminium extrusions idlula izinto eziningi ezivame ukusetshenziswa ekuhlolweni kokumelana nokugqwala.

- Isendlalelo se-oxide esakhiwe ku-aluminium sinikeza isivikelo esihlala isikhathi eside, sinciphisa izindleko zokulungisa futhi sinwebe isikhathi sokuphila sezingxenye.

- Ukwelapha okungaphezulu, okufana ne-anodizing, kungathuthukisa ukumelana nokugqwala, kwenze i-aluminium ibe inketho ekhanga kakhulu kubathengi be-OEM.

| Uhlobo Lokwelapha | Incazelo | Izinzuzo |

|---|---|---|

| I-anodizing | Inqubo ye-Electrochemical yokuguqula i-aluminium ibe yi-aluminium oxide (Al₂O₃) | Ukumelana nokugqoka okuphezulu, ukuzinza okuhle kakhulu kwe-dimensional |

| Passivation | Ivikela indawo ekugqwaleni futhi inikeza isisekelo sokumboza | Ukumelana nokugqwala okuthuthukisiwe, ukumelana okungaguquki kwe-conductivity kagesi |

| I-Polymer Coatings | Isendlalelo esengeziwe sokuvikela sisetshenziswa phezu kwe-aluminium | Ukuqina okuthuthukisiwe nokukhanga kobuhle |

Ukuvumelana nezimo

Ukuguquguquka kokuklama kwamaphrofayili e-aluminium extrusion akuqhathaniswa. Ungakha izimo eziyinkimbinkimbi kanye nemininingwane eyinkimbinkimbi okunzima ukuyifinyelela ngezinye izinto. Inqubo ye-extrusion ivumela umumo namakhonsathi ahlukene ahlukene, okukuvumela ukuthi wenze ngendlela oyifisayo izingxenye ukuze uhlangabezane nezidingo ezithile zephrojekthi.

- Izici Zokuguquguquka Komklamo:

- Ama-Aluminium extrusions avumela imiklamo eyinkimbinkimbi kanye nokufakwa kwezici eziningi kuphrofayela eyodwa.

- Amajiyometri ayinkimbinkimbi, njengezingxenye ezingenalutho namaphethelo ayindilinga, angakhiqizwa ngaphandle kokubeka engcupheni ubuqotho bezinto ezibonakalayo.

- Lokhu kuzivumelanisa nezimo kuholela ekwandeni kokusebenza kahle, ubuhle, kanye nokwenza kube ngokwakho ezimbonini ezahlukahlukene.

Ikhono lokuhlanganisa izixazululo ezihambisana nezidingo ezithile zokusebenza, zesakhiwo, nezobuhle kubalulekile ekuthuthukiseni imiklamo. Ngokusebenzisa amaphrofayili e-aluminium extrusion, ungathuthukisa amandla nokuhlanganisa ngenkathi unciphisa isidingo sokucutshungulwa kwangemuva, okuholela ekwenzeni ngcono ukusebenza kahle kokukhiqiza kanye nokwehliswa kwezindleko.

Ukusebenza Kwezindleko Zephrofayili Ye-Aluminium Extrusion

Ukulahlwa Kwezinto Ezincishisiwe

Amaphrofayili e-aluminium extrusion anciphisa kakhulu udoti wezinto ezibonakalayo ngesikhathi sokukhiqiza. Ungakwazi ukufinyelela lokhu ngokusebenzisa amasu athuthukile amaningana:

- Idizayini ye-Die Optimized: Ukusebenzisa isofthiwe yokuklama eyinkimbinkimbi ikuvumela ukuthi ulingise ukuhamba kwezinto futhi ubikezele amaphutha. Le ndlela inganciphisa amazinga okulahlwa afinyelela ku-30%.

- Izinhlelo Zokulawula Izinqubo Ezithuthukile: Ukuqapha kwesikhathi sangempela kwemingcele ye-extrusion kungaholela ekunciphiseni ngo-10-20% esizukulwaneni se-scrap.

- Amasu Okunciphisa I-Scrap: Ukusebenzisa ukusika okunembayo nokubamba okuzenzakalelayo kusiza ukunciphisa amaphutha namaphutha.

- Izimiso Zokukhiqiza Ezinciphile: Ukusebenzisa izindlela ezifana neSix Sigma kukwenza ukwazi ukuhlonza nokuqeda imithombo yokulahlwayo ngempumelelo.

- Ubuchwepheshe obufana ne-AI kanye ne-Digital Twins: Ukusebenzisa i-AI ukuze kutholwe ukukhubazeka kanye namawele edijithali ekulingiseni izinqubo kungaqhubeka nokugwema udoti wezinto ezibonakalayo.

Ngokusebenzisa la masu, awugcini nje ngokuthuthukisa ukusebenza kahle kodwa futhi ufaka isandla ekusimameni ezinqubweni zakho zokukhiqiza.

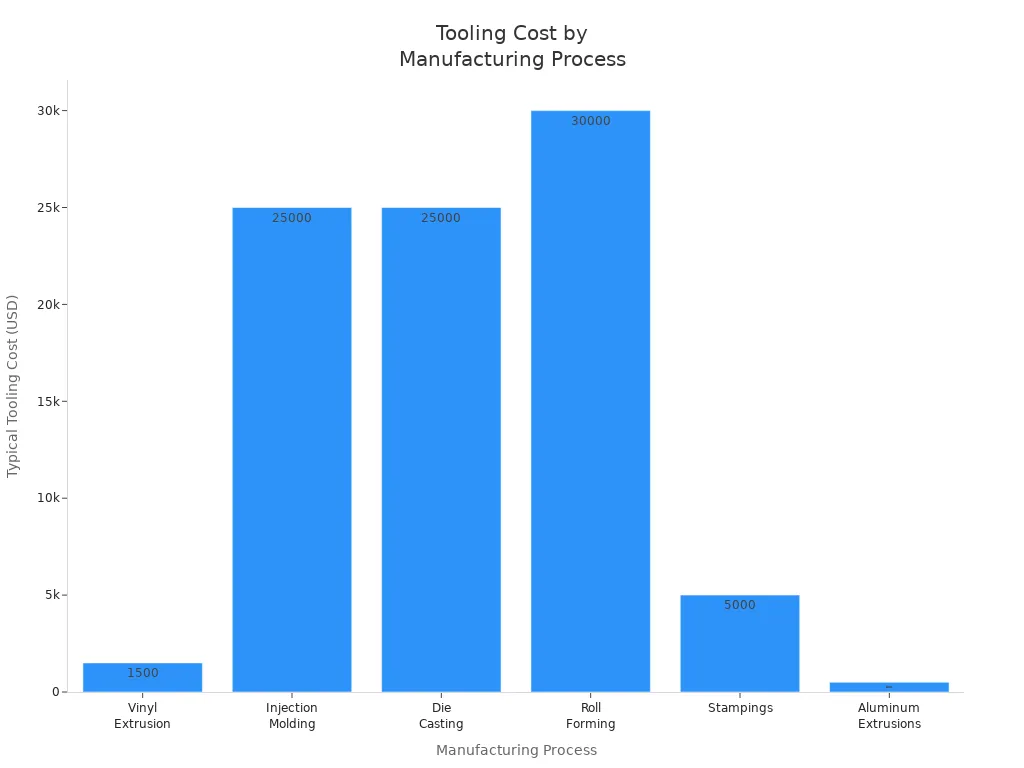

Izindleko Zokukhiqiza Eziphansi

Uma uqhathanisa amaphrofayili e-aluminium extrusion nezinye izindlela zokukhiqiza, uzothola ukuthi i-aluminium inikezaukonga izindleko ezinkulu. Izindleko zamathuluzi ezihambisana ne-aluminium extrusion ziphansi kakhulu kunezinye zensimbi noma zepulasitiki. Nakhu ukuhlukaniswa kwezindleko zamathuluzi ezijwayelekile:

| Inqubo Yokukhiqiza | Izindleko Zamathuluzi Ezijwayelekile |

|---|---|

| I-Vinyl Extrusion | $1,500+ |

| Ukubunjwa komjovo | $25,000+ |

| I-Die Casting | $25,000+ |

| Ukwakhiwa kweRoll | $30,000+ |

| Izitembu | $5,000+ |

| I-Aluminium Extrusions | $500-$5,000 |

Leli thebula libonisa ukuthi amaphrofayili e-aluminium extrusion angakwazi kanjani ngokuphawulekayonciphisa utshalomali lwakho lokuqalaekusetshenzisweni kwamathuluzi. Ukwengeza, ukusetshenziswa kwamandla kanye nezindleko zabasebenzi ezihambisana ne-aluminium extrusion ziyaqhudelana. Ngokuvamile, i-aluminiyamu eluhlaza ibalelwa ku-60-70% wezindleko eziphelele, kuyilapho abasebenzi kanye ne-overheads benza ama-20-30%, futhi izindleko zamandla zivela ku-10-15%.

Ukonga Isikhathi Eside

Ukutshala imali kumaphrofayili e-aluminium extrusion kuholela ekongeni isikhathi eside. Esikhathini esiyiminyaka emihlanu, uzobona izindleko eziphansi zokulungisa nokushintsha uma kuqhathaniswa nezinsimbi zamagalani kanye ne-PVC. Ukuqina kwe-aluminium kusho ukuthi uzochitha imali encane ekunakekeleni, okuholela ekwehleni kwezindleko zomjikelezo wokuphila.

- Ukuphila isikhathi eside kwe-aluminium kunciphisa imvamisa yokulungiswa.

- Insimbi enama-galvanized, kuyilapho ekuqaleni ishibhile, ingenisa izindleko zokulungisa eziphakeme nokushintshwa ngenxa yokuqina kwayo okuphansi.

Ngokukhetha amaphrofayili e-aluminium extrusion, awongi kuphela ezindlekweni zokuqala kodwa futhi ujabulele izinzuzo zokulungiswa okuncishisiwe nokuqina okuthuthukisiwe ngokuhamba kwesikhathi.

Ukusetshenziswa kwamaphrofayili e-Aluminium Extrusion ku-Customing Tooling kanye nomjovo wePlastiki

Tooling Frameworks

Amaphrofayili e-aluminium extrusion adlala indima ebalulekile ekudaleni izinhlaka eziqinile zamathuluzi. Ungakwazi ukusebenzisa isilinganiso samandla nesisindo ukuze uthuthukise ubuqotho besakhiwo kuyilapho ugcina isisindo siphansi. Lesi sici sizuzisa kakhulu ezimbonini ezifana nezokwakha, ezezimoto, kanye ne-aerospace. Nakhu ukubuka konke okusheshayo kokusetshenziswa okuvamile emikhakheni eyahlukene:

| Imboni | Ukusetshenziswa Okuvamile |

|---|---|

| Ukwakha | Amawindi, iminyango, amafreyimu |

| Ezezimoto | Izingxenye ezingasindi zezimoto |

| I-Aerospace | Izingxenye zesakhiwo |

| Ezogesi | Amasinki okushisa, izivalo |

| Amandla Avuselelekayo | Uhlaka lwamaphaneli elanga |

Idizayini ye-modular yamaphrofayili e-aluminium ivumela ukwenza ngokwezifiso okulula nokuhlakazwa, okuthuthukisa ukusebenza nokuvumelana nezimo kuzinhlaka zamathuluzi.

Izingxenye Zesikhunta

In amaphrojekthi omjovo wepulasitiki, amaphrofayili e-aluminium extrusion athuthukisa isikhathi sokuphila nokusebenza kwezingxenye zesikhunta. I-thermal conductivity enhle kakhulu isiza ukushisisa nokupholisa ngokushesha, okunciphisa izikhathi zomjikelezo wokubumba. Lokhu kusebenza kahle kuholela ekwandeni kokukhiqiza. Ukwengeza, i-aluminium kulula ukuyifaka ngomshini, enciphisa ukugqokwa kwamathuluzi futhi isheshise ukwenziwa. Nazi ezinye izinzuzo zokusebenzisa i-aluminium ezingxenyeni zesikhunta:

| Izinzuzo/Imikhawulo | Incazelo |

|---|---|

| I-Thermal Conductivity | Ihambisa imijikelezo esheshayo yokushisisa nokupholisa, inciphise izikhathi zomjikelezo wokubumba futhi ikhulise ukusebenza kahle. |

| Ukusebenziseka kalula | Kulula ukwenza umshini, ukunciphisa ukugqokwa kwamathuluzi nokwandisa isivinini sokusika, okuholela ekwenziweni okusheshayo. |

| Izindleko-Ngempumelelo | Ivamise ukubiza kancane kunezinye izinto, okuyenza ilungele ukukhiqizwa kwevolumu ephansi. |

Isivinini Sokukhiqiza Esithuthukisiwe

Amaphrofayili e-aluminium extrusion athinta kakhulu isivinini sokukhiqiza kumathuluzi wangokwezifiso kanye nezicelo zokujova zepulasitiki. Inqubo ye-extrusion isebenza ngamanani okuphakelayo okusheshayo, kusukela ku-2 kuya ku-20 ft/min, okunciphisa izikhathi zokuhola nezindleko. Nansi indlela amaphrofayili e-aluminium athuthukisa ngayo isivinini sokukhiqiza:

| Isici | Umthelela Esivinini Sokukhiqiza |

|---|---|

| Isivinini Senqubo Yokukhipha | Amazinga okuphakelayo okusheshayo anciphisa izikhathi zokuhola nezindleko. |

| I-Tooling Complexity | Amaphrofayili ayinkimbinkimbi anganciphisa inqubo ye-extrusion. |

| Izindleko-Ngempumelelo | Ukukhiqiza okusheshayo kuholela ezindlekweni eziphansi ingxenye ngayinye. |

Ngokwamukela amaphrofayili e-aluminium extrusion, ungafinyelela ukumoshwa kwezinto ezingavuthiwe okuncane ngenkathi ugcina imiklamo engasindi ngaphandle kokudela ukusebenza. Izinkampani ezishintshele ku-aluminium extrusion zibike ukukhuphuka okungafika ku-30% ekusebenzeni kahle kokukhiqiza, okubonisa izinzuzo zezinto ezibonakalayo ekukhiqizeni kwesimanje.

Ukushintshela kuma-extrusions e-aluminium kubangelwa izici zawo ezingasindi, ezihlala isikhathi eside, nezingabizi kakhulu. Uzuza izinzuzo ezibalulekile ngokukhetha amaphrofayili e-aluminium extrusion wamathuluzi akho angokwezifiso namaphrojekthi omjovo wepulasitiki. Lawa maphrofayili athuthukisa ukuguquguquka kwedizayini futhi anciphise izindleko zokukhiqiza, okuholela emiphumeleni ethuthukisiwe yephrojekthi kanye nomphetho wokuncintisana emakethe.

FAQ

Yiziphi izinzuzo eziyinhloko zokusebenzisa ama-aluminium extrusions?

Ama-Aluminium extrusions anikeza amandla angasindi, ukumelana nokugqwala, kanye nokuguquguquka kwedizayini, okuwenza alungele ukusebenzisa amathuluzi ngokwezifiso namaphrojekthi omjovo wepulasitiki.

I-aluminium extrusions iqhathaniswa kanjani nezinye izinto?

Ama-Aluminium extrusions alula futhi amelana nokugqwala kunensimbi, ahlinzeka ngokusebenza kahle kwezindleko nempilo ende uma kuqhathaniswa nezinye izinto zepulasitiki.

Ingabe i-aluminium extrusions ingenziwa ngezifiso izinhlelo zokusebenza ezithile?

Yebo, ungenza ngendlela oyifisayo ama-extrusions e-aluminium ukuze ahlangabezane nezidingo ezithile zephrojekthi, okuhlanganisa ukwakheka okuyinkimbinkimbi nosayizi abaklanyelwe izidingo zakho.

Isihloko: Kungani Abathengi be-OEM Bephendukela Ku-Aluminium Extrusions ngo-2025,

Incazelo: Abathengi be-OEM bakhetha amaphrofayili e-aluminium extrusion ngo-2025 ngezixazululo zabo ezingasindi, ezingabizi kakhulu, neziguquguqukayo kumaphrojekthi wamathuluzi angokwezifiso kanye nomjovo.,

Amagama angukhiye: Iphrofayili ye-Aluminium Extrusion