Ukubumba komjovo okunembayo kudlala indima ebalulekile ekuthuthukiseni ukwakheka kwezimoto. Ithuthukisa kakhulu ukusebenza kahle nokusebenza ngokwakha izingxenye ezingasindi, njengamaphrofayili e-aluminium extrusion, anomthelela ekusebenzeni kahle kukaphethiloli. Ukwengeza, ukukhiqizwa kweizingxenye zepulasitiki zemotongokusebenzisa le nqubo emisha kunciphisa udoti wezinto ezibonakalayo, ukunikeza isisombululo esingabizi esizuzisa kokubili abakhiqizi kanye nemvelo. Ngaphezu kwalokho, ubuchwepheshe bungasetshenziselwa ukudala izingxenye ezikhethekile ezifana ne-rectangle linear drain shower drains kanye namashubhu ethusi okupholisa amapuleti ethusi, okubonisa ukuguquguquka kwawo ekusetshenzisweni okuhlukahlukene.

Okuthathwayo Okubalulekile

- Ukubumba komjovo okunembayo kuthuthukisa idizayini yezimoto ngokudalaizingxenye ezingasindi, ukuthuthukisa ukusebenza kahle kukaphethiloli, nokunciphisa ukumosha izinto ezibonakalayo.

- Le nqubo inikeza ukuguquguquka okukhethekile komklamo, okuvumela ukuma okuyinkimbinkimbi nokuhlanganiswa kwezinto ezihlukene engxenyeni eyodwa.

- Ukwamukela ukubumba komjovo okunembayo kuholela ekongeni kwezindleko ezinkulu ngokunciphisa imfucuza kanye nokuthuthukisa izinqubo zokukhiqiza, okukwenza kubaluleke ekukhiqizeni okunokuncintisana.

Izinzuzo Zokubumba Umjovo Oqondile

Ukubumba komjovo okunembayo kunikeza izinzuzo eziningi ezithuthukisa kakhulu ukwakheka kwezimoto. Ngokusebenzisa le nqubo yokuqamba izinto ezintsha, ungafinyelela intuthuko emangalisayo ekululameni kwedizayini, ukusebenza kahle kwezinto ezibonakalayo, kanye nokusebenza kahle kwezindleko.

Ukuvumelana nezimo

Enye yezinzuzo ezivelele zokubumba umjovo ngokunemba kuyinto ehlukileukuguquguquka komklamo. Le nqubo ikuvumela ukuthi udale amajiyometri ayinkimbinkimbi futhi ayinkimbinkimbi ezinye izindlela zokukhiqiza ezilwela ukuwafinyelela. Nazi ezinye izici ezibalulekile zokuguquguquka kwedizayini:

- Ukubunjwa kwe-Multi-shot kanye ne-overmolding kukwenza ukwazi ukuhlanganisa izinto eziqinile nezithambile engxenyeni eyodwa. Lokhu kuthuthukisa ukusebenza nokunethezeka ngenkathi kunciphisa izinyathelo zokuhlanganisa.

- Ikhono lokukhiqiza izimo eziyinkimbinkimbi, ezifana ne-undercuts nezindonga ezincane, zivula umhlaba wamathuba omklamo wezingxenye zezimoto.

- Amasu okubumba athuthukile asekela ukuhlanganiswa kwezinto ezihlukahlukene, okuvumela imiklamo emisha ehlangabezana nezidingo ezithile zokusebenza.

Ngokubumba okunembayo komjovo, ungakwazi ukusunduza imingcele yedizayini yezimoto, udale izingxenye ezingasebenzi kuphela kodwa futhi ezijabulisa ngobuhle.

Ukusebenza Kwezinto Ezibalulekile

Ukusebenza kahle kwezintokungenye inzuzo ebalulekile yokubumba umjovo ngokunemba. Le nqubo inciphisa imfucuza futhi ikhulise ukusetshenziswa kwezinto ezingavuthiwe, okubalulekile emakethe yanamuhla ekhathalela imvelo. Cabangela amaphuzu alandelayo:

- Izinkampani zivamise ukwehliswa ngo-25–40% kudoti kanye nokukhubazeka uma kusetshenziswa ukubumba okunembayo. Lokhu kusho ukuthi ungakhiqiza izingxenye eziningi ngezinto ezincane.

- Ngokwesilinganiso, u-98% wempahla eluhlaza ethengiwe isetshenziswa emikhiqizweni yokugcina ngale ndlela. Leli zinga eliphezulu lokusebenza kahle lihumusha ekongeni kwezindleko ezibalulekile.

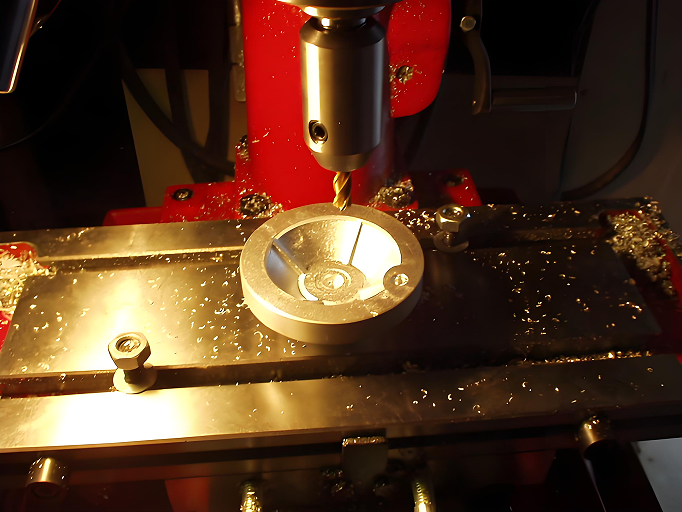

- Le nqubo ihilela ukuncibilikisa inhlaka yepulasitiki, ukuyijova esikhunjeni esenziwe ngomshini ngokunemba, nokuyipholisa ukuze kwakhe izingxenye zezimoto eziyinkimbinkimbi. Lokhu kuqinisekisa ukuthi ufinyelela amazinga aphezulu emininingwane nokunemba, okubalulekile ezingxenyeni eziyinkimbinkimbi njengamadeshibhodi namaphaneli eminyango.

Ngokwamukela ukubumba komjovo okunembayo, awuthuthukisi nje kuphela ikhwalithi yezingxenye zemoto yakho kodwa futhi ufaka isandla emizamweni yokusimama ngokunciphisa udoti wezinto ezibonakalayo.

Izindleko-Ngempumelelo

Ukusebenza kahle kwezindleko kuwukucatshangelwa okubalulekile kunoma yimuphi umkhiqizi wezimoto. Ukubumba umjovo oqondile kuyaphumelela kule ndawo ngokunciphisa udoti wezinto ezibonakalayo nokuthuthukisa izinqubo zokukhiqiza. Nansi indlela:

- Ukukhiqizwa kwevolumu ephezulu kwehlisa izindleko zeyunithi ngayinye ngokusabalalisa izindleko zokuqala zokusetha phezu kwezingxenye ezengeziwe. Lokhu kwenza kube ukonga kumaqoqo amakhulu.

- Ubuchwepheshe obuthuthukisiwe njenge-CAD buthuthukisa inqubo yokuklama, kuthuthukisa ukusetshenziswa kwezinto ezibonakalayo kanye nokunciphisa izindleko zokukhiqiza zizonke.

- Isu livumela ukusetshenziswa kahle kwezinto, okuholela ekongeni okubalulekile.

Ukwengeza, izinzuzo zesikhathi eside zokusebenzisa ukubumba komjovo ngokunemba zifaka ukusebenza kahle okuphezulu nesivinini, imiphumela yekhwalithi ephezulu, kanye nomnotho wesikali. Lezi zici zihlangene zifaka isandla enqubweni yokukhiqiza engabizi kakhulu, eqinisekisa ukuthi uhlala uncintisana embonini yezimoto.

Ngokwamukela ukubumba komjovo okunembayo, ungafinyelela ibhalansi yekhwalithi, ukusebenza kahle, nokonga izindleko, ukwenze kube yithuluzi elibalulekile ekwakhiweni kwezimoto zesimanjemanje.

Izinhlelo zokusebenza ku-Automotive Components

Ukubumba komjovo oqondile kudlala indima ebalulekile ekukhiqizweni kwezingxenye zezimoto ezahlukahlukene. Le nqubo ithuthukisa ukusebenza, ukuqina, kanye nokukhanga kobuhle bezingxenye ezindaweni ezahlukene zokwakheka kwemoto. Ake sihlole ukuthi ukubumba komjovo okunembayo kusebenza kanjani ezingxenyeni zenjini, izingxenye zangaphakathi, namaphaneli angaphandle.

Izingxenye Zenjini

Izingxenye zenjini zizuza kakhulu ekubumbeni umjovo ngokunemba. Le ndlela ikuvumela ukuthi ukhiqize izingxenye ezingasindi kodwa eziqinile, ezibalulekile ekuthuthukiseni ukusebenza kwemoto nokusebenza kahle kukaphethiloli. Izingxenye zenjini ezivame ukukhiqizwa zihlanganisa:

- Izinhlobo eziningi zokungenisa umoya

- Izembozo ze-valve

- Izindlu zezinzwa

- Izixhumi zikagesi

Ukusebenzisa izinto ezifana ne-polyamide (PA) ne-polyphenylene sulfide (PPS) kuqinisekisa ukuthi lezi zingxenye zimelana namazinga okushisa aphezulu kanye nezimo zokusebenza ezinzima. Izinzuzo zokusebenzisa ipulasitiki ezingxenyeni zenjini zifaka:

- Ukunciphisa Isisindo: Izingxenye ezingasindi zithuthukisa ukusebenza kwemoto iyonke.

- Ukuqina: Ukubumba komjovo okunembayo kuthuthukisa amandla nokuthembeka kwezingxenye, kuzenze zibe ukushintshwa okufanelekile kwezingxenye zensimbi zendabuko.

| Zuza | Incazelo |

|---|---|

| Izinto ezisebenza kahle kakhulu | Isebenzisa ama-thermoplastics amelana nezindawo ezinokhahlo, ithuthukisa amandla nokuthembeka. |

| Imiklamo eyinkimbinkimbi | Ivumela ukwakhiwa kwezingxenye eziyinkimbinkimbi ezinokubekezelelana okuqinile, okuqinisekisa ikhwalithi engaguquki. |

| Ukushintshwa kwezingxenye zensimbi | Iyakwazi ukukhiqiza izingxenye ezingangena esikhundleni sensimbi, okunomthelela ekuqineni okuphelele. |

Izingxenye Zangaphakathi

Ukubumba komjovo oqondile nakho kushintsha ukukhiqizwa kwezingxenye zezimoto zangaphakathi. Le nqubo ivumela ukudalwa kwejometri eyinkimbinkimbi nemiklamo ehlanganisiwe ethuthukisa kokubili ukusebenza nobuhle. Izingxenye ezibalulekile zangaphakathi ezikhiqizwa ngale ndlela zihlanganisa:

- Amadeshibhodi

- Amapaneli eminyango

- Iziqeshana nezinsimbi

Izinzuzo zokubumba umjovo zalezi zingxenye ziningi:

| Uhlobo Lwengxenye | Izinzuzo Zokubumba Umjovo |

|---|---|

| Amadeshibhodi | Umumo oyinkimbinkimbi, ukuqina, ukukhanga kobuhle |

| Amaphaneli eminyango | Ukuphindaphinda okuphezulu, amandla |

| Iziqeshana kanye Fasteners | Ukunemba, ukungaguquguquki ekukhiqizeni |

Ngaphezu kwalokho, ukubumba komjovo okunembayo kukuvumela ukuthi ufinyelele amaphethelo abushelelezi nemibala engokwezifiso ehambisana nomklamo wemoto. Leli khono lithuthukisa ukukhanga okubonakalayo kwezingxenye ezifana nezinqumo ezenziwe ngokwezifiso nama-knob egiya, azenze zingasebenzi kuphela kodwa futhi zikhange.

Amaphaneli Angaphandle

Uma kukhulunywa ngamaphaneli angaphandle, ukubumba komjovo okunembayo kunikeza izinzuzo ezimangalisayo. Le nqubo ivumela ukukhiqizwa kwezingxenye ezingasindi ezithuthukisa ukusebenza kahle kwe-aerodynamic nokukhanga okubonakalayo. Izinzuzo ezibalulekile zifaka:

- Ukunemba okuphezulu ekukhiqizeni izimo eziyinkimbinkimbi, ezibalulekile ezingxenyeni zezimoto eziyinkimbinkimbi.

- Ikhono lokudala amaphaneli angaphandle angasindi athuthukisa ukusebenza kwemoto kukonke.

- Izithuthukisi zobuhle ngokuqedwa okubushelelezi nemininingwane eyinkimbinkimbi.

Ukuhlukahluka kokubumba komjovo kusekela ukwakhiwa kwezingxenye ezihlangabezana kokubili okulindelwe ukusebenza nobuhle. Lokhu kuqinisekisa ukuthi amaphaneli angaphandle awenzi kahle nje kuphela kodwa futhi anomthelela ekwakhiweni kwemoto iyonke.

Izibonelo Zezifundo Zokusebenzisa Okuyimpumelelo

I-Ningbo Tiehou Auto Parts Co., Ltd. Innovations

I-Ningbo Tiehou Auto Parts Co., Ltd. iyisibonelo sokuqamba okushaukunemba umjovo ekubumbeningaphakathi komkhakha wezimoto. Isungulwe ngo-2018, le nkampani inesipiliyoni seminyaka engaphezu kwengu-20 kulo mkhakha. Ukuzibophezela kwabo ekuklameni nasekukhiqizeni ubuhle kuholele ekuthuthukisweni kwezingxenye ezisezingeni eliphezulu zezinhlelo zokusebenza zezimoto ezahlukahlukene.

Ukugxila kwabo ekusimameni nasezisombululweni ezigxile kumakhasimende kube nenqubekela phambili enkulu. Ngokwesibonelo, bahlanganise ngempumeleloamasu okubumba ama-multi-shotukukhiqiza izingxenye eziyinkimbinkimbi ezihlanganisa izinto ezahlukene. Lokhu okusha akugcini nje ngokuthuthukisa ukusebenza kodwa futhi kunciphisa isikhathi sokuhlanganisa, okwenza inqubo yokukhiqiza isebenze kahle.

Amaphrofayili e-Aluminium Extrusion asebenza

Amaphrofayili e-aluminium extrusion adlala indima ebalulekile ekwehliseni isisindo semoto ngenkathi egcina amandla. Lawa maphrofayili anezilinganiso eziphezulu zamandla nesisindo, okuwenza alungele izingxenye zemoto ezibucayi. Nazi ezinye izinzuzo ezibalulekile:

- Ukuguqula ukwakheka kwemoto okumhlophe-mhlophe (BIW) ukusuka ensimbi kuya ku-aluminium kungaholela ekwehlisweni kwesisindo cishe ngama-40% ezingxenyeni ezilungisiwe.

- Izakhiwo eziyingqayizivele ze-aluminium, njengokuhamba kokushisa namandla, zithuthukisa ukusetshenziswa kwayo ezingxenyeni ezihlukahlukene zemoto.

- Izingxenye ezingasindi njengamabhampa nezingxenye zozimele zifaka isandla ekuthuthukiseni ukusebenza kahle kukaphethiloli kanye nokusebenza kwemoto kukonke.

Ngokusebenzisa amaphrofayili e-aluminium extrusion, abakhiqizi bangakwazi ukuzuza ukonga isisindo esibalulekile, okubalulekile ekwakhiweni kwezimoto zanamuhla.

Amathrendi Azayo Ekukhiqizeni Izimoto

Njengoba imboni yezimoto ithuthuka, ukubumba okunemba komjovo kuyaqhubeka nokubamba iqhaza elibalulekile ekulolongeni amathrendi wokukhiqiza wesikhathi esizayo. Ungalindela ukuthuthuka okuphawulekayo ezintweni zokwakha kanye nokuhlanganiswa kobuchwepheshe obusezingeni eliphezulu ukuze kuthuthukiswe ukusebenza kahle kokukhiqiza nokuzinza.

Intuthuko Kwezinto Zokusebenza

Umkhakha wezimoto ufakaza ukwanda kwezinto ezisetshenziswayo ezithuthukisa ukusebenza kahle futhi ezinciphisa umthelela kwezemvelo. Nazi ezinye zentuthuko ezibalulekile:

- Izingxenye zeHybrid: Lezi zihlanganisa ipulasitiki nensimbi, zikhulise amandla kuyilapho zinciphisa isisindo.

- I-Carbon Fiber Composites: Bahlinzeka ngesixazululo esingasindi esithuthukisa ukusebenza kahle kukaphethiloli futhi sinciphise ukungcola.

- Izinsimbi Zamandla Aphakeme Ezithuthukile (AHSS): Lezi zinto zinikeza amandla aphakeme, okuvumela ukunciphisa isisindo ngaphandle kokudela ukusebenza.

- I-Bio-based and Recycled Plastics: Lezi ezinye izindlela ezilungele imvelo zisiza ukunciphisa udoti nezindleko zokukhiqiza.

Imakethe yama-thermoplastics aqiniswe nge-fiber eqhubekayo kulindeleke ukuthi ikhule kakhulu, ikhombisa isidingo esinamandla sezinto ezilula ezihlangabezana nemithetho eqinile yezemvelo.

Ukuhlanganiswa Nobunye Ubuchwepheshe

Ukuhlanganiswa kobuchwepheshe obuthuthukisiwe kuguqula ukubumba komjovo ngokunemba. Ungalindela ukubona:

- Okuzenzakalelayo: Ukwenyuka kokukhiqizwa kwe-automation streamlines, ukuthuthukisa ukunemba nokunciphisa izindleko zabasebenzi.

- I-Artificial Intelligence (AI): I-AI ithuthukisa izinqubo zokukhiqiza, ithuthukisa ikhwalithi futhi yehlise imfucuza. Isebenzisa idatha yenzwa ye-high-frequency ukubikezela iphutha nokulawula inqubo.

- Imboni 4.0 Izimiso: Le migomo ithuthukisa izinqubo zokukhiqiza, iqinisekisa ukuthi ufinyelela ukunemba ekwakhiweni kwezimoto.

| Ubuchwepheshe | Umthelela |

|---|---|

| Okuzenzakalelayo | Lulanisa ukukhiqizwa, kuthuthukisa ukunemba, futhi kunciphisa izindleko zabasebenzi. |

| AI | Iguqula ukubumba komjovo ngokunemba, ithuthukisa ukusebenza kahle kanye nekhwalithi. |

| Imboni 4.0 | Isebenzisa ubuchwepheshe obuhlakaniphile ukuthuthukisa izinqubo zokukhiqiza ekwakhiweni kwezimoto. |

Ngokwamukela lezi ntuthuko, ungathuthukisa ukusebenza kahle nokusimama kokukhiqizwa kwezimoto, ubeke imiklamo yakho ukuze uphumelele esikhathini esizayo.

Ukubumba komjovo okunembayo kubalulekile ekwakhiweni kwezimoto zesimanjemanje. Ikuvumela ukuthi udaleizingxenye ezingasindi, njengamaphrofayili e-aluminium extrusion, athuthukisa ukusebenza kwemoto. Le nqubo iphinde isekele ukusimama ngokuthuthukisa ukusetshenziswa kwezinto ezibonakalayo kanye nokunciphisa ukukhishwa kwekhabhoni. Ngokulandela imihlahlandlela yokuklama enemininingwane, ungaqinisekisa ikhwalithi nokusebenza kahle kwezingxenye ezibunjiwe, ukuvimbela ukwehluleka kokukhiqiza nokugcina ubuqotho besakhiwo.

| Zuza | Incazelo |

|---|---|

| Ukusimama | Ubuchwepheshe besimanje ekubumbeni umjovo bubhekana nezinselelo zemvelo ngokusebenzisa izinto ezisimeme kanye nezinqubo ezisebenza kahle. |

| Udoti Owehlisiwe | Ukubumba umjovo kunciphisa udoti, kusetshenziswa kuphela inani lepulasitiki elidingekayo emkhiqizweni wokugcina. |

| Ukusebenza Kwamandla | Imishini yesimanje yenzelwe ukonga amandla, inciphisa kakhulu izindleko zokusebenza. |

FAQ

Kuyini ukubumba okunemba komjovo?

Ukubumba umjovo oqondile kuyinqubo yokukhiqiza edala inkimbinkimbiizingxenye zepulasitikingokunemba okuphezulu kanye nemfucuza encane.

Ukubumba umjovo oqondile kuthuthukisa kanjani ukusebenza kahle kukaphethiloli?

Ngokukhiqiza izingxenye ezingasindi, ukubumba umjovo ngokunemba kunciphisa isisindo semoto, okuholela ekusebenzeni kahle kukaphethiloli nokusebenza.

Yiziphi izinto ezisetshenziswa kakhulu ekubumbeni umjovo ngokunemba kwezingxenye zezimoto?

Izinto ezijwayelekile zifaka i-polyamide (PA), i-polyphenylene sulfide (PPS), nama-thermoplastic ahlukahlukene anikeza ukuqina nokumelana nokushisa.