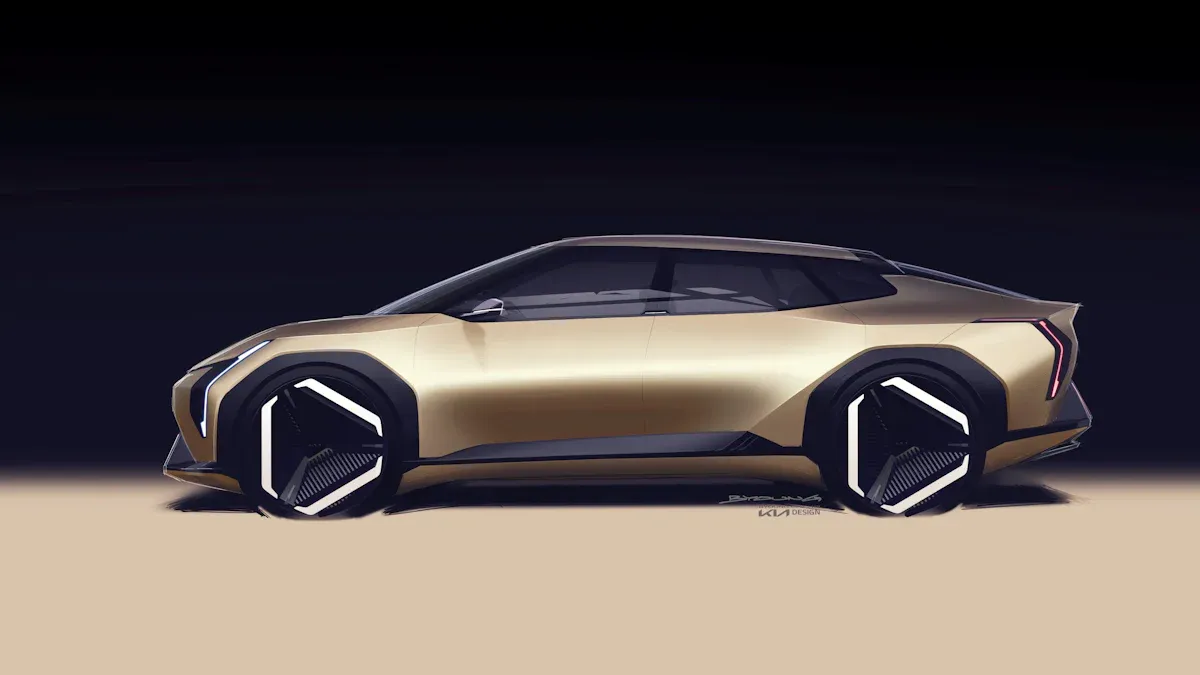

Amaphrofayili e-aluminium extrusion ashintsha igeyimu ekukhiqizeni izimoto. Uyazuza ekwakhiweni okuvumelana nezimo okuthuthukisiwe, okuvumela ukwakheka kwezimoto ezintsha. Izakhiwo ezingasindi zalawa maphrofayili zisiza ukwehlisa isisindo semoto sisonke, okuthuthukisa ukusebenza kahle kukaphethiloli futhi kwehlise nekhabhoni. Imakethe ye-automotive aluminium extrusion yaziswa ngayoI-USD 76.58 billion ngo-2023futhi kulindeleke ukuthi ifinyelele ku-USD 147.08 bhiliyoni ngo-2031. Lokhu kukhula kubonisa ukuguquguquka okunamandla okuya emikhubeni eqhubekayo kanye nesidingo esikhulayo sezimoto zikagesi, ezithembele ezintweni ezingasindi ukuze zisebenze kahle.

Okuthathwayo Okubalulekile

- Amaphrofayili e-Aluminium extrusion anciphisa isisindo semoto, athuthukise ukusebenza kahle kukaphethiloli kanye nokunciphisa ukungcola. Lokhu kungaholela ekwehlisweni kwesisindo esingamakhilogremu angama-35 ngemoto ngayinye.

- Lawa maphrofayili athuthukisa ukuphepha kwemoto ngokumunca amandla omthelela phakathi nokushayisana. Idizayini yabo ivumela ukuguqulwa okungcono, okuthuthukisa ukuphahlazeka.

- Amaphrofayili e-Aluminium extrusion anjaloengabizi ngokuhamba kwesikhathi. Nakuba izindleko zokuqala zamathuluzi zingase zibe phezulu, ngokuvamile ziholela ezindlekweni eziphansi zokunakekela kanye nokuqina okungcono.

- Ukusebenzisa i-aluminiumisekela ukusimamaembonini yezimoto. Ingaqukatha kufika ku-75% okuqukethwe okugaywe kabusha futhi i-aluminiyamu yokugaya kabusha isebenzisa amandla angaphansi kwama-95% kunokukhiqiza i-aluminium entsha.

- Amaphrofayili e-aluminium anemisebenzi eminingi ekwakhiweni kwezimoto, afaneleka izingxenye zesakhiwo, izici zobuhle, nezinhlelo zokuphatha ezishisayo, athuthukisa kokubili ukusebenza nesitayela.

Izinzuzo ze-Aluminium Extrusion Profiles

Izakhiwo Ezingasindi

Amaphrofayili e-aluminium extrusion anciphisa kakhulu isisindo semoto, okuthinta ngokuqondile ukusebenza nokusebenza kahle. Ngokusebenzisa lawa maphrofayili, ungafinyelela isilinganiso sokunciphisa isisindo cishe35 opondo imoto ngayinye. Lokhu kwehliswa kulindeleke ukuthi kukhuphuke cishe45 opondo imoto ngayinyengo-2025. Ukonga okunjalo kwesisindo kuholela ekusebenzeni okuthuthukisiwe kophethiloli kanye nokukhipha umoya omncane, okwenza izimoto zakho zivumelane nemvelo. Eqinisweni, izinhlangano ze-aluminium ezisetshenziswayo zingaholela ku-Ukuncipha kwesisindo somzimba ngama-35%.uma kuqhathaniswa nozakwabo bensimbi bendabuko. Le nzuzo engasindi ibalulekile njengoba imboni yezimoto ishintshela ezindleleni ezizinzile.

Amandla Athuthukisiwe Nokuqina

Ungase umangale ukwazi ukuthi amaphrofayili e-aluminium extrusion awanikezi nje kuphela izinzuzo ezingasindi kodwa futhi anikeza amandla athuthukisiwe nokuqina. Izici zemishini ye-aluminium zifaka isandla emazingeni okuphepha kwemoto. Isibonelo, amandla okudonsa amaphrofayili e-aluminium extrusion aqala ukusuka180-220 MPa, kuyilapho amandla okukhiqiza angafinyelela90-140 MPa. Uma kuqhathaniswa, insimbi yendabuko ngokuvamile inamandla okudonsa455 MPakanye namandla okukhiqiza we380 MPa. Kodwa-ke, ikhono le-aluminium lokumunca amandla ngesikhathi somthelela liyenza ibe ukukhetha okuphephile ekwakhiweni kwemoto. Iphesenti lokwelulwa kwe-aluminium, elisukela koku10-25%, ivumela ukuguqulwa okungcono ngaphandle kokwehluleka, okuthuthukisa ukuphepha kwemoto jikelele.

Izindleko-Ngempumelelo

Uma ucabangelaizindleko zokukhiqiza, amaphrofayili e-aluminium extrusion anikeza inketho yokuncintisana. Nakuba izindleko zokuqala zamathuluzi e-aluminium zingase zibe phezulu ngenxa yokuthuthukiswa kokufa kanye nezingubo ezikhethekile, izinzuzo zesikhathi eside zivame ukudlula lezi zindleko. Isibonelo, izindleko zokulungisa ezihambisana nezimoto ezisebenzisa amaphrofayili e-aluminium zivame ukuba ngaphansi ngokuhamba kwesikhathi. Ukuhlaziywa kwezindleko zomjikelezo wokuphila okuvamile kuveza ukuthi izimoto ze-aluminum zidinga ukulungiswa nokunakekelwa kancane uma kuqhathaniswa nozakwabo bensimbi.

| Uhlobo Lwezinto | Izindleko Factors | Ukuqhathanisa ne-Aluminium |

|---|---|---|

| I-Aluminium | Izindleko eziphakeme zamathuluzi, ukuthuthukiswa kokufa, izambatho ezikhethekile | Ngokuvamile ephakeme kunensimbi ngenxa yamathuluzi namanani wezinto ezibonakalayo |

| Insimbi | Izindleko zamathuluzi eziphansi, amanani wokunyathela ngokushesha | Ibiza kakhulu kune-aluminium ezinhlelweni eziningi |

| Inhlanganisela | Iyahluka ngokuya ngesicelo | Ukusebenza kahle kwezindleko kungaba nokuncintisana kuye ngenqubo |

Izinzuzo Ukusimama

Amaphrofayili e-aluminium extrusion adlala indima ebalulekile ekuthuthukiseni ukusimama embonini yezimoto. Izakhiwo zabo ezilula azigcini nje ngokuthuthukisa ukusebenza kahle kukaphethiloli kodwa futhi zinciphisa kakhulu ukukhishwa kwegesi ngesikhathi sokusebenza kwemoto. Ngokukhetha i-aluminium, ungasiza izimoto zakho ukuthi zihlangabezane nemigomo nemithethonqubo eqinile Yezemvelo, Ezenhlalakahle, Nokubusa (ESG). Nazi ezinye izinzuzo ezibalulekile zokusimama zokusebenzisa amaphrofayili e-aluminium extrusion:

- Ukusetshenziswa kwamandla: Ukukhiqizwa kwe-aluminium kudinga amandla amaningi, okungathinta ukukhishwa kwekhabhoni. Kodwa-ke, imvelo engasindi ye-aluminium isiza ukuthuthukisa ukusebenza kahle kukaphethiloli, okuholela ekukhiqizweni okuphansi kokusebenza.

- Izinzuzo Zokugaywa kabusha: Enye yezinzuzo ezibaluleke kakhulu ze-aluminium ukugaywa kwayo kabusha. Ukusetshenziswa kabusha kwe-aluminiumAmandla angaphansi ngo-95%.kunokukhiqiza i-aluminium entsha ngezinto ezingavuthiwe. Le nqubo iholela ekwehleni okukhulu kokukhishwa kwegesi.

- Ukukhetha Okubalulekile: Ukukhethwa kwe-aluminium kuthonya isisindo semoto, ukusetshenziswa kwamandla, kanye nomthelela olingana ne-carbon dioxide (CO2e). Ngokukhetha amaphrofayili e-aluminium extrusion, ufaka isandla enqubweni yokukhiqiza eqhubekayo.

- Ukuphepha Kokuhlinzekwa Kwesikhathi Eside: Ukusebenzisa i-aluminium kuthuthukisa ukubikezelwa kwezindleko nokusimama. Lokhu kuzinza kubalulekile njengoba imboni yezimoto ibhekene nezindleko zempahla ezishintshayo kanye nezinselelo ze-supply chain.

Ithebula elilandelayo lifingqa ukuthi amaphrofayili e-aluminium extrusion ayithinta kanjani i-carbon footprint yokukhiqiza izimoto:

| Isici | Umthelela ku-Carbon Footprint |

|---|---|

| Ukusetshenziswa kwamandla | Ukukhiqizwa kwe-aluminium kudinga amandla amaningi, kuthinta ukukhishwa kwegesi. |

| Izakhiwo Ezingasindi | Ithuthukisa ukusebenza kahle kukaphethiloli, inciphise ukukhishwa kwekhabhoni yokusebenza. |

| Izinzuzo Zokugaywa kabusha | Ukugaywa kabusha kwe-aluminiyamu kusebenzisa amandla angaphansi kwama-95% kunokukhiqiza okuyinhloko, okuholela ekukhiqizweni okuphansi. |

| Ukukhetha Okubalulekile | Ithonya isisindo semoto, ukusetshenziswa kwamandla, nomthelela we-CO2e. |

| Ukuphepha Kokuhlinzekwa Kwesikhathi Eside | Ithuthukisa ukubikezelwa kwezindleko kanye nokusimama. |

Ngaphezu kwalokho, kuze kube75%ye-aluminium esetshenziswa kumaphrofayili e-extrusion wezinhlelo zokusebenza zezimoto ingavela kokuqukethwe okugaywe kabusha kwangemuva komthengi. Leli zinga eliphezulu lokugaywa kabusha aligcini nje ngokulondoloza izinsiza kodwa futhi linciphisa umthelela wemvelo ohlobene nokukhipha izinto ezingavuthiwe.

Ngokuhlanganisa amaphrofayili e-aluminium extrusion kumiklamo yakho yezimoto, ufaka isandla ekusaseni elizinze kakhudlwana. Inhlanganisela yezinto ezingasindi, ukusebenza kahle kwamandla, namandla okugaywa kabusha kubeka i-aluminium njengento ehamba phambili ekufuneni izixazululo zezimoto eziluhlaza.

Izinhlelo zokusebenza ze-Aluminium Extrusion Profiles ku-Automotive Design

Amaphrofayili e-aluminium extrusionidlala indima ebalulekile ekwakhiweni kwezimoto zesimanje, ithuthukisa kokubili ukusebenza nobuhle. Ukuhlukahluka kwazo kukuvumela ukuthi uzisebenzise ezinhlelweni ezihlukahlukene, kusukela ezingxenyeni zesakhiwo kuye ezicini zobuhle eziyinkimbinkimbi.

Izingxenye Zesakhiwo

Ungathola amaphrofayili e-aluminium extrusion ezingxenyeni ezimbalwa ezibalulekile zesakhiwo sezimoto. Lawa maphrofayili anikeza amandla adingekayo ngenkathi enciphisa kakhulu isisindo. Izicelo ezijwayelekile zifaka:

- Izingxenye ze-Chassis: Lawa maphrofayili ahlinzeka ngobuqotho besakhiwo, okuqinisekisa ukuthi imoto ihlala iqinile kodwa ingasindi.

- Izakhiwo zokuphahlazeka: Zimunca amandla omthelela, zithuthukise ukuphepha kwabagibeli ngesikhathi sokushayisana.

- Izivalo Zebhethri: Ezimotweni zikagesi, lawa maphrofayili avikela izingxenye ezizwelayo, aqinisekisa ukuthi ziphila isikhathi eside futhi zithembekile.

- Amafreyimu Omzimba: Ibalulekile ekugcineni ukwakheka kwayo yonke imoto.

- Izingxenye ze-Chassis: Izingxenye ezibalulekile ezisekela isisindo kanye nokuzinza kwemoto.

- Amasistimu Okulawula Ukuphahlazeka: Okubalulekile ekuphepheni, lawa masistimu asebenzisa amaphrofayili e-aluminium ukuze anciphise ukulimala ngesikhathi sezingozi.

Amaphrofayili e-aluminium extrusion athuthukisa ukuphahlazeka ezingxenyeni zesakhiwo sezimoto. Isibonelo, ukusebenzisa lawa maphrofayili kungaholela ku-aisaphulelo sika-4.74%.emthwalweni omkhulu ngesikhathi semithelela. Ukwengeza, bangakhuphula ukumuncwa kwamandla7%, okuthuthukisa ukuphepha kwemoto kukonke.

| Ukuthola | Incazelo |

|---|---|

| Ukwehliswa Komthwalo Ophakeme | Kufikela ekunciphiseni okungu-4.74% komthwalo ophezulu (Pmax) ngokunqanyulwa. |

| Ukwenyuka Kokumuncwa Amandla | Ukwenyuka okungu-7% kokumuncwa kwamandla (i-Ea) okuphawulwe ngokungaqhubeki. |

| Crush Force Efficiency | Ukwenyuka okungu-12.69% ekusebenzeni kahle kwe-crush force (CFE) okuphawulwe ngokunqanyulwa kwemishini. |

Izici zobuhle

Amaphrofayili e-Aluminium extrusion nawo anegalelo elikhulu ekukhangekeni kobuhle bezimoto. Izinzuzo zabo zokuklama zivumela inhlanganisela yokusebenza nesitayela. Izinzuzo ezibalulekile zifaka:

| Inzuzo | Incazelo |

|---|---|

| Isilinganiso samandla nesisindo | I-Aluminium ilula kunensimbi kuyilapho igcina amandla esakhiwo esiphezulu, ilungele ukusetshenziswa kwezimoto. |

| Ukuvumelana nezimo | I-extrusion yangokwezifiso ivumela amaphrofayili ayinkimbinkimbi futhi ayinkimbinkimbi, athuthukisa kokubili ukusebenza nobuhle. |

| Ukumelana nokugqwala | Ukumelana kwemvelo kwe-aluminiyamu ukugqwala kuyenza ifanelekele izinhlelo zezimoto ezivezwe ezindaweni ezahlukahlukene. |

Ungenza ngokwezifiso ingaphandle lemoto nengaphakathi usebenzisa amaphrofayili e-aluminium extrusion. Lokhu ngokwezifiso kufaka izakhiwo zomzimba, izingxenye ze-chassis, nezingxenye zangaphakathi. Isibonelo, ungadizayina amafreyimu edeshibhodi enziwe ngendlela efanele kanye nabakaki bezihlalo ezithuthukisa kokubili ubuhle nokusebenza.

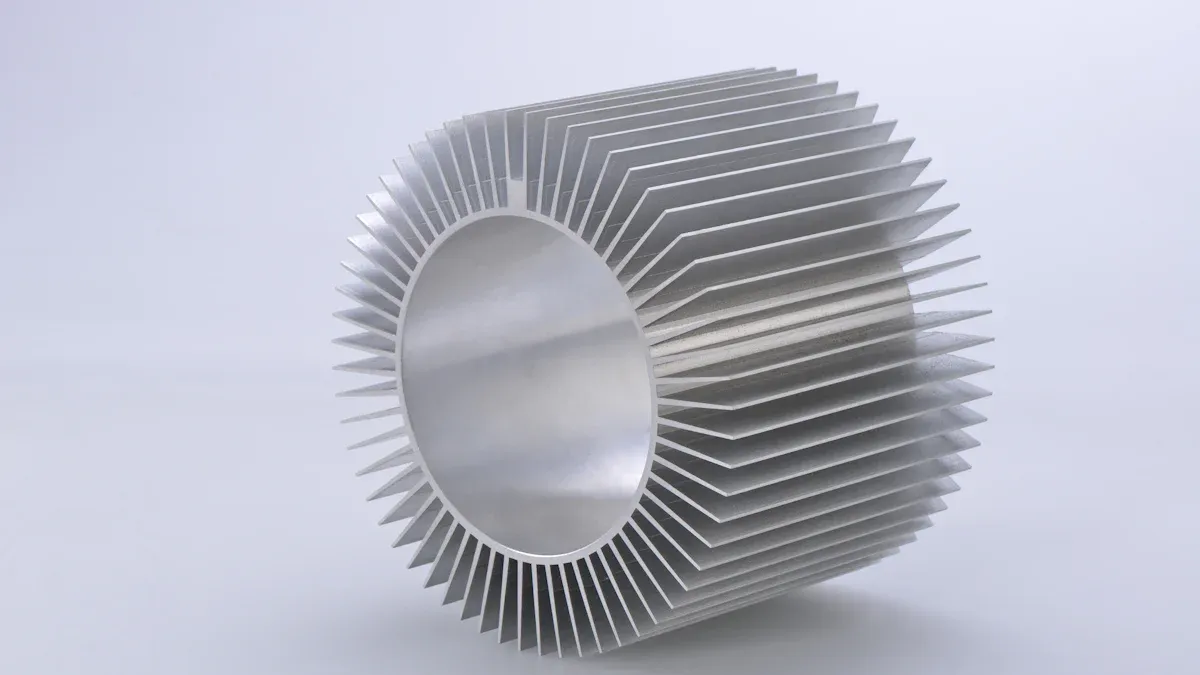

Ama-Heat Exchanger namaRadiators

Kuzinhlelo zokupholisa izimoto, amaphrofayili e-aluminium extrusion ahamba phambili ekusebenzeni kahle. Zenziwe ngendlela ehlukileukusebenza okushisayo, ukuqinisekisa ukushintshaniswa kokushisa okufanelekile. Izici ezibalulekile zifaka:

| Isici | Incazelo |

|---|---|

| Ukusebenza Okushisayo | Iklanyelwe ukusebenza kwe-thermal okukhethekile, iqinisekisa ukushintshaniswa kokushisa okuphelele. |

| Ukuqina | Gxila ekuqineni kokusetshenziswa okuhlala isikhathi eside ezinhlelweni ezihlukahlukene. |

| Idizayini Engasindi | Ilungele ukucushwa okubanzi kwerediyetha ngenxa yezakhiwo ezingasindi. |

Ama-alloys e-aluminium, afana ne-6061 kanye ne-6063, aziwa ngokushisa kwawo okuphezulu. Lesi sakhiwo sibalulekile ekulawuleni ukushisa okusebenzayo kumasistimu okupholisa izimoto. Imvelo yabo engasindi kanye nokuguquguquka ekwakhiweni kwabo kuqhubekisela phambili ukufaneleka kwabo kulezi zinhlelo zokusebenza.

Ngokuhlanganisa amaphrofayili e-aluminium extrusion emiklamo yezimoto zakho, awuthuthukisi nje kuphela ubuqotho besakhiwo nobuhle kodwa futhi uthuthukisa ukuphathwa kokushisa, okwenza izimoto zakho zisebenze kahle futhi zihehe.

Okusha Ezimotweni zikagesi Ezisebenzisa amaphrofayili e-Aluminium Extrusion

Izixazululo Zezindlu Zebhethri

Ungathuthukisa kakhulu ukuphepha nokusebenza kahle kwezimoto zikagesi ngokusebenzisaamaphrofayili e-aluminium extrusionyezindlu zamabhethri. Lawa maphrofayili anikeza amaninganaizinzuzo ezibalulekile:

- Ukuqina: Aqinisekisa ukuthi amaphakethe ebhethri avikelwe kahle emithelelaneni.

- Engasindi: Lokhu kunomthelela ekwehliseni isisindo okubalulekile, okubalulekile ekusebenzeni kahle kwemoto kagesi.

- Ukuthobela Umthetho: Amaphrofayili e-aluminium ahlangabezana nezindinganiso zokuphepha ezivalekile zebhethri.

- Umhlangano Owenziwe Lula: Benza lula ukwakhiwa kwamamojula webhethri.

- I-Electromagnetic Shielding: Lokhu kuvikela izingxenye ze-elekthronikhi ekuphazamisekeni.

- Ukumuncwa Amandla: I-Aluminium isebenza kangcono ezimeni zokuphahlazeka uma iqhathaniswa nezinye izinto.

Ngokusebenzisa i-aluminium, uzuza ekunciphiseni isisindo kuze kufike50%uma kuqhathaniswa nezivalo zebhethri lensimbi yendabuko. Lokhu konga ngobuningi kuthuthukisa uhla lwemoto nokusebenza kahle kwamandla.

I-Lightweight Chassis Design

Amaphrofayili e-aluminium extrusion adlala indima ebalulekile ekuklameni i-chassis engasindi yezimoto zikagesi. Ngokufaka insimbi esikhundleni se-aluminium, ungakwazi ukufeza ukuncishiswa kwesisindo25-30%. Lokhu kunciphisa kuthuthukisa ukusheshisa nokusebenza kahle kwamandla. Ubuqotho besakhiwo be-aluminium buqinisekisa ukuthi ibhethri lihlala livikelekile ngesikhathi sokuphahlazeka, okuthuthukisa amandla e-chassis wonkana.

| Zuza | Incazelo |

|---|---|

| Ubuqotho besakhiwo | Ivikela ibhethri ngesikhathi sokuphahlazeka, ithuthukisa amandla e-chassis wonkana. |

| Ukuphatha okushisayo | Ichitha ukushisa okukhiqizwa ngesikhathi sokushaja nokusebenza, okubalulekile ekuphepheni kwebhethri. |

| Ukuvikela okulula | Ilinganisa isisindo sebhethri, ithuthukisa ukusebenza kahle kwemoto kanye nobubanzi. |

| Ukwenza ngokwezifiso | Iziteshi ezihlanganisiwe zokupholisa nokufaka izintambo zinciphisa ubunkimbinkimbi bomklamo nokubalwa kwezingxenye. |

| Amasistimu okuphatha ukuphahlazeka | Iklanyelwe ukonakala ngokubikezelwa ngaphansi komthelela, imunca amandla futhi ivikele abagibeli. |

Amasistimu Okulawula Okushisayo

Ukuphatha okushisayo okusebenzayo kubalulekile ekusebenzeni nokuhlala isikhathi eside kwezimoto zikagesi. Amaphrofayili e-aluminium extrusion ahamba phambili kule ndawo ngenxa yemvelo yawo yokushisa eshisayo. Ungasebenzisa ama-aluminium extrusions ngokwezifiso ezindlini zebhethri namapuleti okupholisa ukuze uthuthukise ukuphathwa kokushisa.

- Ukusebenza kahle kokushisa okuphezulu: Lokhu kuthuthukisa impilo yebhethri nokusebenza.

- Imvelo engasindi: Inomthelela ekusebenzeni kahle kwemoto iyonke, ikakhulukazi phakathi nezimo ezidingeka kakhulu.

- Amashubhu okupholisa ama-Serpentine: Yenziwe nge-aluminium extruded, lezi zithuthukisa ukugeleza kokupholisa, zigcina izinga lokushisa elifanele lamaseli ebhethri.

Ngokuhlanganisa amaphrofayili e-aluminium extrusion ezinhlelweni zakho zokuphatha ezishisayo, uqinisekisa ukuthi imoto yakho esebenza ngogesi isebenza kahle nangokuthembekile.

Ukuqhathaniswa kwamaphrofayela e-Aluminium Extrusion Nezinto Zomdabu

Insimbi vs. Aluminium

Uma uqhathanisa insimbi ne-aluminium, uzobona umehluko omkhulu ezicini zemishini nasekusetshenzisweni kwayo. Nawa amaphuzu abalulekile okufanele uwacabangele:

- Amandla Okuqina: Izinga lensimbi ukusuka400 MPa ukuze 500 MPa, kuyilapho i-aluminium iseduze90 MPa. Lokhu kubonisa ukuthi insimbi ingakwazi ukumelana nokushuba okukhulu.

- Amandla Acindezelayo: Insimbi idlula i-aluminium, ithwala imithwalo ephakeme ngaphandle kokuguquka okubalulekile.

- Isivuno Amandla: Amandla okukhiqiza ensimbi amayelana250 MPa, uma kuqhathaniswa ne-aluminium40 MPa, ukukhombisa amandla ensimbi.

Ngenkathi i-aluminiumelula, amandla aphezulu ensimbi avumela imiklamo emincane, ethuthukisa amakhono okuthwala umthwalo. Kodwa-ke, imvelo ye-aluminium engasindi iyenza ifanele izinhlelo zokusebenza lapho ukwehlisa isisindo kubaluleke kakhulu.

Izinto Ezihlanganisiwe

Izinto ezihlanganisiwe zinikeza izinzuzo eziyingqayizivele ezinhlelweni zezimoto. Bahlanganisa izinto ezahlukene ukuze kuzuzwe ukusebenza okuphezulu. Nansi indlela abaqhathanisa ngayo namaphrofayili e-aluminium extrusion:

- Isisindo: Izinhlanganisela zingaba lula kune-aluminium, kuye ngezinto ezithile ezisetshenzisiwe.

- Amandla: Ezinye izinhlanganisela zibonisa izilinganiso eziphezulu zamandla nesisindo, okuzenza ziqhudelane ne-aluminium kwezinye izinhlelo zokusebenza.

- Izindleko: Ngokuvamile, izinhlanganisela zingabiza kakhulu kune-aluminium ngenxa yezinqubo zokukhiqiza eziyinkimbinkimbi.

Amaphrofayili e-aluminium extrusionzihlale ziyinketho edumile ngenxa yebhalansi yazo yezindleko, isisindo, namandla, okuzenza zilungele izinhlelo zokusebenza zezimoto ezahlukahlukene.

Amamethrikhi okusebenza

Lapho kuhlolwa amamethrikhi okusebenza, amaphrofayili e-aluminium extrusion ahamba phambili ezindaweni ezimbalwa:

- Izilinganiso Zokuhlola Ukuphahlazeka: Ama-alloys e-aluminium, ikakhulukazi lawo aku-5xxx uchungechunge, baziwa ngamandla abo aphezulu kanye nokuminyana okuphansi. Le nhlanganisela ithuthukisa ukusebenza kokuphahlazeka.

- Ukonga Isisindo: Amaphrofayili e-Aluminium angafinyelela ukonga isisindo kuze kufike25%uma kuqhathaniswa nezakhiwo zensimbi zendabuko. Lokhu kuncishiswa kunomthelela ekwenzeni ngcono ukusebenza kahle kukaphethiloli kanye nokunciphisa intuthu.

- Ukumuncwa Amandla: I-Aluminium ingakwazi ukumunca amandla ngokuphumelelayo ngesikhathi sokuphahlazeka, ithuthukise ukuphepha kwabagibeli.

Amathrendi Esikhathi esizayo Nezinselele zamaphrofayili e-Aluminium Extrusion

Intuthuko ku-Extrusion Technology

Ungalindela intuthuko ebalulekileubuchwepheshe be-aluminium extrusionlokho kuzobumba imboni yezimoto. Nazi ezinye izinto ezibalulekile okufanele uzibuke:

- Ukunciphisa Ukukhishwa Kwekhabhoni: Abakhiqizi bagxile ekunciphiseni ukukhishwa kwekhabhoni kukho konke ukusakaza kwenani lokukhiqiza kwe-aluminium. Lolu shintsho lukhuthaza ukusimama futhi luqondanise nezinhloso zezemvelo zomhlaba wonke.

- Higher Amandla Alloys: Ukuthuthukiswa kwamandla aphezulu 6000 uchungechunge lwe-aluminium alloys kuthuthukisa ukuqina kuzinhlelo zokusebenza zezimoto. Lawa ma-alloys ahlinzeka ngokusebenza okungcono kakhulu ngenkathi egcina izici ezingasindi.

- Amakhono Okukhipha I-Micro-Extrusion: Ukwethulwa kwe-micro-extrusion kuvumela ukukhiqizwa kwamaphrofayili amancane kakhulu. Leli khono libalulekile ekudaleni izingxenye ezimotweni zikagesi, lapho ukugcinwa kwesikhala kanye nesisindo kubalulekile.

Izidingo Zemakethe kanye Nezinkinga Zochungechunge Lokuhlinzeka

Imakethe yamaphrofayili e-aluminium yezimoto ibhekene nezinselelo ngenxaukushintshashintsha kwentengo yezinto ezibonakalayo. Ungase uqaphele ukuthi izindleko zama-aluminum ingots namabhilidi zithonywa ukuphazamiseka kochungechunge lokuhlinzekwa komhlaba wonke, izintengo zamandla, kanye nokungezwani kwezwe. Lezi zici zenza kube nzima ikhono lakho lokuphatha izindleko zokukhiqiza ngempumelelo. Ukwengeza, ukushoda kwabasebenzi kanye nezingqinamba zezokuthutha zivimbela ama-extruder e-aluminium ekuhlangabezaneni nezidingo zokulethwa okufika ngesikhathi. Ngenxa yalokho, ungase ube nokulibaziseka noma izindleko ezikhuphukile ekutholeni amaphrofayili e-aluminium amaphrojekthi akho ezimoto.

Ukucatshangelwa Kwezokulawula Nezemvelo

Imithethonqubo yezemveloidlala indima ebalulekile ekwamukelweni kwamaphrofayili e-aluminium extrusion embonini yezimoto. Nawa amathonya abalulekile:

- Imithethonqubo ikhuthaza ukusetshenziswa kwezinto ezingasindi ukuze kuhlangatshezwane namazinga okukhipha umoya.

- Amazinga aqinile wokonga uphethiloli kanye neziyalezo zokufakwa kukagesi kukhuthaza ukwamukelwa kwamaphrofayili e-aluminium.

- Imithetho emayelana nokuphinda isetshenziswe kabusha kanye nemigomo yezomnotho eyindilinga iqhuba ukusungulwa kwezinqubo zokugaywa kabusha kwe-aluminium.

- Inguquko ebheke ezimotweni zikagesi (EVs) isheshiswa yizingcindezi ezilawulayo, okwandisa isidingo sezingxenye ze-aluminium.

Ngokuhlala unolwazi mayelana nalawa mathrendi nezinselele, ungakwazi ukuzulazula kangcono indawo eguqukayo yamaphrofayili e-aluminium extrusion emkhakheni wezimoto.

Ukuhlanganiswa kwamaphrofayili e-aluminium extrusion kuguqula kakhulu imboni yezimoto. Uzuza ezimotweni ezilula ezithuthukisa ukusebenza kahle kukaphethiloli futhi ezinciphisa ukukhishwa kwekhabhoni. Lawa maphrofayili futhi asekela imiklamo emisha, ekuvumela ukuthi udale izimoto ezihlangabezana nezindinganiso zesimanje zokusimama. Njengoba imboni ithuthuka, ukwamukela amaphrofayili e-aluminium extrusion kuzobaluleka ukuze uhlale unokuncintisana futhi unomthwalo wemfanelo wemvelo.

FAQ

Ayini amaphrofayili e-aluminium extrusion?

Amaphrofayili e-aluminium extrusionziyizimo ezidalwe ngokuphoqelela i-aluminium ngokusebenzisa idayisi. Le nqubo ivumela abakhiqizi ukuthi bakhiqize izimo eziyinkimbinkimbi ezingasindi, ezinamandla, neziguquguqukayo zezinhlelo zokusebenza zezimoto ezahlukahlukene.

Amaphrofayili e-aluminium extrusion akuthuthukisa kanjani ukuphepha kwemoto?

Lawa maphrofayili amunca amandla omthelela ngesikhathi sokushayisana, athuthukisa ukuphepha kwabagibeli. Idizayini yabo ivumela ukuwohloka okungcono ngaphandle kokwehluleka, okufaka isandla ekwenzeni ngcono ukuphahlazeka kwezimoto.

Ingabe amaphrofayili e-aluminium extrusion ayabiza?

Yebo, nakuba izindleko zokuqala zamathuluzi zingase zibe phezulu, amaphrofayili e-aluminium ngokuvamile aholela ezindlekweni eziphansi zokulungisa ngokuhamba kwesikhathi. Ukuqina kwazo kanye nemvelo engasindi kungaholela ekongeni okubalulekile ekusebenzeni kahle kukaphethiloli.

Iyiphi indima edlalwa amaphrofayili e-aluminium extrusion ezimotweni zikagesi?

Ezimotweni zikagesi, amaphrofayili e-aluminium extrusion abalulekile ezindlini zamabhethri, imiklamo ye-chassis engasindi, nezinhlelo zokuphatha ezishisayo. Bathuthukisa ukuphepha, ukusebenza kahle, nokusebenza kwemoto iyonke.

Asimama kangakanani amaphrofayili e-aluminium extrusion?

Amaphrofayili e-Aluminium extrusion anjaloesimeme kakhulu. Angaqukatha kufika ku-75% okuqukethwe okugaywe kabusha, futhi ukugaya kabusha i-aluminium kusebenzisa amandla angaphansi kwama-95% kunokukhiqiza i-aluminium entsha, kunciphisa kakhulu umthelela wendawo.