Ukukhetha inqubo yokukhiqiza efanele yezingxenye zensimbi zangokwezifiso kubalulekile. Udinga ukucabangela izici ezifana nokunemba, umthamo, nezindleko. I-CNC machining inikezela ngokunemba okungenakuqhathaniswa nokuvumelana nezimo, okuyenza ilungele ukugijima okuncane kwezingxenye eziyinkimbinkimbi. Ngakolunye uhlangothi, ukukhishwa kwensimbi kudlula ukukhiqizwa kwevolumu ephezulu ngenxa yezindleko zayo kanye nesivinini. Indlela ngayinye inamandla kanye nemikhawulo yayo. Izidingo zakho ezithile zizonquma ukuthi iyiphi inqubo ekufanele kakhulu. Ukuqonda lo mehluko kukusiza ukuthi wenze izinqumo ezinolwazi, uqinisekise ukuthi izingxenye zakho zihlangabezana nokucaciswa okufunayo kanye nekhwalithi.

Imishini ye-CNC Yezingxenye Zensimbi Ejwayelekile

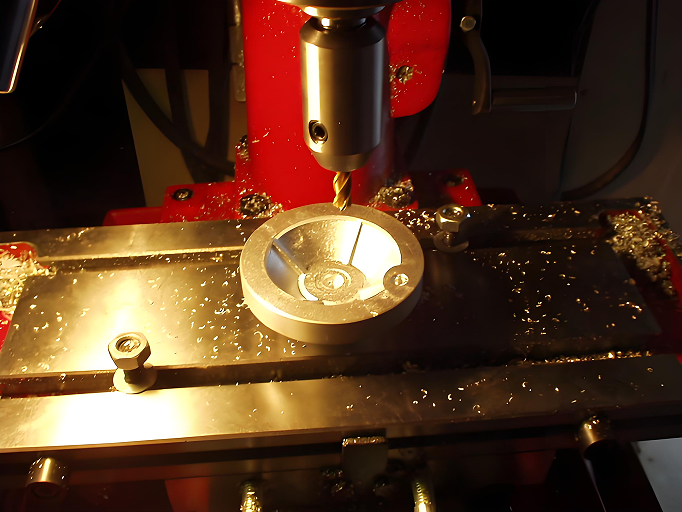

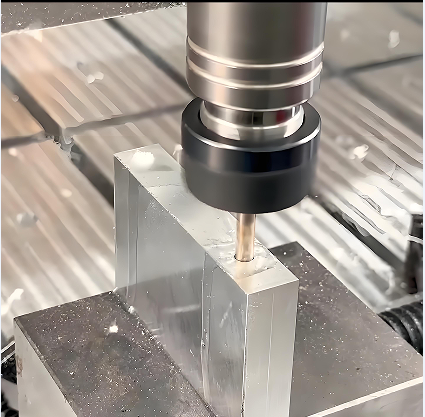

CNC Machining Operations

I-CNC machining ime njengenqubo yokukhiqiza eguquguqukayo ekuvumela ukuthi udale izingxenye zensimbi ezenziwe ngokwezifiso ngokunemba okumangazayo. Le nqubo ihilela ukusetshenziswa kwemishini elawulwa yi-computer ukuze ilolonge insimbi ibe izinhlobo ezifiselekayo. Ungakwazi ukufeza imiklamo eyinkimbinkimbi namajiyometri ayinkimbinkimbi angase abe inselele ngezinye izindlela. Imishini ye-CNC isebenza ngokulandela imiyalelo ehleliwe, iqinisekisa ukuthi ingxenye ngayinye ihlangabezana nezimfuneko eziqondile. Lokhu kunemba kwenza imishini ye-CNC ilungele ukukhiqiza izingxenye ezinembe kakhulu ezinokubekezelelana okuqinile, ikakhulukazi lapho usebenza nezingxenye ezincane noma ze-niche.

Izinzuzo CNC Machining

Uma ukhetha ukwenza imishini ye-CNC yezingxenye zakho zensimbi ngokwezifiso, uthola izinzuzo ezimbalwa:

- Ukunemba okuphezulu: Imishini ye-CNC ihamba phambili ekuletheni izingxenye ngokunemba okukhethekile. Lokhu kubalulekile uma udinga izingxenye ezilingana kahle kumaassemblies amakhulu.

- Imiklamo Eyinkimbinkimbi: Ikhono lokukhiqiza imiklamo eyinkimbinkimbi neyinkimbinkimbi ihlukanisa imishini ye-CNC. Ungakha izingxenye ezinezici ezinemininingwane ezinye izinqubo ezingase kube nzima ukuziphindaphinda.

- Ukuqina: Izingxenye ezikhiqizwe ngomshini we-CNC zaziwa ngokuqina kwazo. Lokhu kuqina kuqinisekisa ukuthi izingxenye zakho zimelana nezinhlelo zokusebenza ezinzima.

- I-Material Versatility: Imishini ye-CNC isebenza ngezinhlobonhlobo zezinto zokwakha, ikuvumela ukuthi ukhethe inketho engcono kakhulu yezidingo zakho ezithile.

- Ukusebenza kahle: Ngokukhiqiza okuphakathi kuya kokuphezulu, ukwenza imishini ye-CNC kunikeza ukusebenza kahle okuhle kakhulu, okwenza kube ukukhetha okubiza izindleko zezingxenye eziqondile.

Imikhawulo ye-CNC Machining

Naphezu kwezinzuzo zayo eziningi, imishini ye-CNC inemikhawulo ethile:

- Izindleko Zevolumu Ephansi: Ngokwenziwa kokukhiqiza okuncane, izindleko zokusetha zokuqala zingaba phezulu. Lokhu kungase kungabi ukukhetha ukonga kakhulu uma udinga izingxenye ezimbalwa kuphela.

- Ukumosha Izinto: Ukwenza imishini ye-CNC kuhilela ukusika izinto, ezingaholela ekumosheni. Lokhu kungase kungabi kuhle uma usebenza ngezinto ezibizayo.

- Ubunkimbinkimbi Ekusetheni: Ukusetha imishini ye-CNC kudinga ama-opharetha anamakhono kanye nezinhlelo ezinembile. Lokhu kuyinkimbinkimbi kungandisa izikhathi zokuhola zamaphrojekthi amasha.

Ngokuqonda lezi zici ze-CNC machining, unganquma kangcono uma kuyinqubo efanele yezingxenye zakho zensimbi zangokwezifiso. Noma ngabe ubeka phambili ukunemba, ubunkimbinkimbi, noma ukuqina, ukwenza imishini ye-CNC kunikeza isisombululo esithembekile sezidingo eziningi zokukhiqiza.

Ukusakaza Kwensimbi Kwezingxenye Zensimbi Ezingokwezifiso

Metal Casting Inqubo

I-Metal casting iyinqubo yokukhiqiza ehlanganisa ukudala isikhunta ukuze ulolonge izingxenye zakho zensimbi ezenziwe ngokwezifiso. Uthela insimbi encibilikisiwe kulesi sikhunta, usivumele ukuba siphole futhi siqine ngokuphelele. Le ndlela ingakhiqiza izingxenye eziyinkimbinkimbi neziyinkimbinkimbi zobukhulu obuhlukahlukene. Amasu ahlukene, afana ne-die casting, enzelwe ukuhlangabezana nezidingo ezithile zokuklama nokukhiqiza. I-die casting, isibonelo, isebenzisa ingcindezi ephezulu ukujova insimbi encibilikisiwe esikhunjeni sensimbi, esingasetshenziswa kabusha izikhathi eziningi. Le nqubo iphumelela kakhulu ekudaleni izingxenye eziyinkimbinkimbi zejometri.

Izinzuzo Zokusakaza Kwensimbi

Uma ukhetha ukusakaza kwensimbi, uthola izinzuzo ezimbalwa:

- Ukuvumelana nezimo: Ukusakaza kwensimbi kukuvumela ukuthi udale izimo eziyinkimbinkimbi namajiyometri ayinkimbinkimbi angase abe inselele ngezinye izindlela.

- Izindleko-Ngempumelelo: Ngokukhiqizwa kwevolumu ephezulu, ukubunjwa kwensimbi kufakazela ukuthi kubiza kakhulu ngenxa yekhono layo lokusebenzisa kabusha isikhunta nokukhiqiza izingxenye ngokushesha.

- I-Material Versatility: Ungasebenzisa izinhlobonhlobo zezinsimbi ekusakazeni, okukunikeza amandla okukhetha into engcono kakhulu yohlelo lwakho lokusebenza.

- Ukukhiqiza Ngempumelelo: Ukulingwa kwensimbi kuhamba kahle kakhulu ekukhiqizeni izingxenye ezinkulu zezingxenye ngendlela efanele, okuyenza ilungele izimboni ezidinga ukukhiqizwa ngobuningi.

Imikhawulo Yokusakaza Kwensimbi

Naphezu kwezinzuzo zako, ukubunjwa kwensimbi kunemikhawulo ethile:

- Izindleko Zokusetha Zokuqala: Ukudala isikhunta kungabiza, ikakhulukazi imiklamo eyinkimbinkimbi. Lokhu kungase kungabi ukonga ekukhiqizeni ivolumu ephansi.

- I-Surface Qeda: Izingxenye ezikhiqizwe ngokulingisa zingase zidinge izinqubo zokuqeda ezengeziwe ukuze kuzuzwe ikhwalithi yendawo efiselekayo.

- Ukunemba kweDimensional: Nakuba ukusakaza kungaveza izimo eziyinkimbinkimbi, ukufeza ukubekezelelana okuqinile kungaba inselele uma kuqhathaniswa nemishini ye-CNC.

Ngokuqonda lezi zici zokulingwa kwensimbi, ungahlola kangcono uma kuyinqubo efanele yezingxenye zakho zensimbi zangokwezifiso. Kungakhathaliseki ukuthi ubeka phambili ukuguquguquka kwedizayini, ukuphumelela kwezindleko, noma ukusebenza kahle kokukhiqiza, ukusakaza kwensimbi kunikeza isisombululo esisebenzayo sezidingo eziningi zokukhiqiza.

Ukuqhathanisa Okuqondile kwe-CNC Machining kanye ne-Metal Casting

Inkimbinkimbi kanye Nomklamo Ovumelana nezimo

Uma kuziwa ekudaleni izingxenye zensimbi zangokwezifiso, kokubili ukwenziwa kwemishini ye-CNC nokusakazwa kwensimbi kunikeza izinzuzo eziyingqayizivele ngokuya ngobunkimbinkimbi nokuguquguquka komklamo.CNC imishiniihamba phambili ekukhiqizeni izingxenye ezinemininingwane eyinkimbinkimbi kanye nokubekezelelana okuqinile. Ungakwazi ukufeza imiklamo enembe kakhulu futhi ephindaphindwayo, okuyenza ilungele izingxenye ezidinga ukucaciswa okuqondile. Le nqubo ivumela ukuguqulwa okulula, okukuvumela ukuthi uhlole futhi ucwenge ama-prototypes ngaphandle kwesidingo sokudala isikhunta esisha.

Ngokolunye uhlangothi,ukubunjwa kwensimbiikhanya ekhonweni layo lokukhiqiza izimo eziyinkimbinkimbi ezinezindonga ezincane kanye nemininingwane eyinkimbinkimbi. Ivumela ukwakhiwa kwezingxenye ezingenalutho kanye nemigodi yangaphakathi okungenzeka kube inselele ukuyifinyelela ngomshini. Nakuba ukusakaza kungase kungafani nokunemba kwemishini ye-CNC, kunikeza ukuguquguquka okubalulekile kwedizayini, ikakhulukazi ukukhiqizwa kwenani elikhulu.

Izindleko Nomthamo Wokukhiqiza

Ukucatshangelwa kwezindleko kudlala indima ebalulekile ekukhetheni phakathi komshini we-CNC kanye nokusakazwa kwensimbi kwezingxenye zakho zensimbi zangokwezifiso.CNC imishinikuvame ukubiza kakhulu ekukhiqizeni ivolumu ephansi ngenxa yezindleko zokusetha kokuqala kanye nokuchithwa kwezinto ezibonakalayo. Kodwa-ke, kuba nezindleko zokukhiqiza ukukhiqiza okuphakathi nendawo kuya phezulu, lapho ukunemba nokuba yinkimbinkimbi kubaluleke kakhulu.

Ngokungqubuzanayo,ukubunjwa kwensimbiikhombisa ukonga kakhulu ekukhiqizeni umthamo omkhulu. Ikhono lokusebenzisa kabusha isikhunta kunciphisa izindleko kakhulu, okwenza kube ukukhetha okuncanyelwayo kokukhiqizwa ngobuningi. Nakuba ukwakhiwa kwesikhunta sokuqala kungase kubize, izindleko zeyunithi ngayinye ziyehla njengoba umthamo wokukhiqiza ukhula. Lokhu kwenza ukusakaza kube inketho esebenzayo ezimbonini ezidinga izingxenye ezinkulu zezingxenye ngokushesha.

Ukuhambisana Kwezinto ezibonakalayo

Ukuhambisana kwezinto kungenye into ebalulekile lapho unquma phakathi kwemishini ye-CNC nokusakazwa kwensimbi.CNC imishiniinikeza izinhlobonhlobo zezinto ongakhetha kuzo, okukuvumela ukuba ukhethe ukwaziswa okungcono kakhulu kwezidingo zakho ezithile. Kungakhathaliseki ukuthi udinga izinsimbi ezifana ne-aluminium, insimbi, noma i-titanium, umshini we-CNC ungahlangabezana nezidingo zakho.

Ukubunjwa kwensimbi, ngenkathi iguquguquka, inezinketho ezilinganiselwe zezinto ezibonakalayo uma kuqhathaniswa nemishini ye-CNC. Isebenza kahle ngezinsimbi ezifana ne-aluminium, i-zinc, ne-magnesium, kodwa ingase ingazifaneli zonke izinto zokwakha. Naphezu kwalokhu mkhawulo, ukulingisa kuhlala kuyisinqumo esithembekile sokukhiqiza izingxenye eziqinile neziqinile.

Ngokuqonda lo mehluko, ungenza izinqumo ezinolwazi mayelana nokuthi iyiphi inqubo evumelana kangcono nezingxenye zakho zensimbi zangokwezifiso. Kungakhathaliseki ukuthi ubeka phambili ukunemba, ukusebenza kahle kwezindleko, noma ukuhambisana kwezinto ezibonakalayo, kokubili ukwenziwa kwemishini ye-CNC nokusakazwa kwensimbi kunikeza izixazululo ezibalulekile zezidingo ezihlukahlukene zokukhiqiza.

Ukukhetha Inqubo Elungile Yezinhlelo Zokusebenza Ezithize

Ukukhetha phakathi komshini we-CNC kanye nokusakazwa kwensimbi kwezingxenye zakho zensimbi zangokwezifiso kudinga ukucatshangelwa ngokucophelela kwezici ezimbalwa. Indlela ngayinye inikeza izinzuzo eziyingqayizivele kanye nemikhawulo, okwenza kube semqoka ukuvumelanisa ukukhetha kwakho nezidingo zakho zohlelo lokusebenza.

Izinto Okufanele Zicabangele

-

Umthamo Wokukhiqiza: Uma udinga inombolo enkulu yezingxenye, ukubunjwa kwensimbi kuvame ukufakazela ukuthi kubiza kakhulu. Ikhono lokusebenzisa kabusha isikhunta kunciphisa izindleko kakhulu ekukhiqizeni umthamo ophezulu. Kodwa-ke, kumaqoqo amancane, ukwenza imishini ye-CNC kungase ukonga naphezu kwezindleko zayo zokusetha eziphezulu.

-

Ukunemba kanye Nokubekezelelana: Imishini ye-CNC ihamba phambili ekuletheni izingxenye ezinokubekezelelana okuqinile nokunemba okuphezulu. Lokhu kuyenza ilungele izinhlelo zokusebenza lapho ukucaciswa okuqondile kubalulekile. Ukubunjwa kwensimbi, ngenkathi ikwazi ukukhiqiza izimo eziyinkimbinkimbi, ingase ingafinyeleli izinga elifanayo lokunemba njengomshini we-CNC.

-

Izidingo Zempahla: Cabangela izinto ohlela ukuzisebenzisa. Imishini ye-CNC inikezela ngohlu olubanzi lwezinketho zezinto ezibonakalayo, ezifaka izinsimbi ezifana ne-aluminium, insimbi, ne-titanium. Ukubunjwa kwensimbi kusebenza kahle ngezinsimbi ezifana ne-aluminium, i-zinc, ne-magnesium kodwa kungase kungahambisani nazo zonke izinto.

-

Design Complexity: Ngemiklamo eyinkimbinkimbi enezici ezinemininingwane, ukwenza imishini ye-CNC kunikeza ukuguquguquka okungenakuqhathaniswa. Ungakwazi ukuguqula kalula imiklamo ngaphandle kokudala isikhunta esisha. Ukubunjwa kwensimbi, nokho, kuvumela ukwakhiwa kwezimo eziyinkimbinkimbi ezinezimbotshana zangaphakathi, okungase kube inselele ukufeza ngomshini.

-

Izindleko Ukucatshangelwa: Linganisa konke okushiwo yizindleko. Nakuba imishini ye-CNC ingase ibe nezindleko eziphezulu zangaphambili, kubiza izindleko zokukhiqiza okuphakathi nendawo ukuya phezulu. Ukukhishwa kwensimbi kunikeza izindleko eziphansi zeyunithi ngayinye ekukhiqizeni ngobuningi, okuyenza ifanele izimboni ezidinga izingxenye ezinkulu zezingxenye ngokushesha.

Izincomo Eziqondene Nemboni

-

Imboni Yezimoto: Ezingxenyeni zezimoto ezidinga ukunemba okuphezulu namandla, umshini we-CNC uvame ukukhethwa. Iqinisekisa ukuthi izingxenye zihlangabezana nezindinganiso zekhwalithi eziqinile futhi zilingana ngokuzenzekelayo kuma-assemblies amakhulu.

-

Imboni ye-Aerospace: Izinhlelo zokusebenza ze-Aerospace zifuna izingxenye ezinemba okukhethekile nokuqina. Imishini ye-CNC ihlinzeka ngokunemba okudingekayo ezingxenyeni ezibalulekile, iqinisekisa ukuphepha nokusebenza.

-

I-Consumer Electronics: Ku-elekthronikhi yabathengi, lapho ubunkimbinkimbi bedizayini nezakhiwo ezingasindi zibalulekile, ukusakaza kwensimbi kungaba inzuzo. Ivumela ukukhiqizwa kobunjwa obuyinkimbinkimbi ngokuphumelelayo.

-

Imishini Yezimboni: Okwemishini yezimboni edinga izingxenye eziqinile neziqinile, ukusakaza kwensimbi kunikeza isisombululo esingabizi kakhulu sokukhiqiza ngobuningi. Inikeza amandla adingekayo kanye nokuvumelana kwezicelo ezifunayo.

Ngokuqonda lezi zici kanye nezincomo eziqondene nomkhakha othile, ungenza izinqumo ezinolwazi mayelana nenqubo yokukhiqiza efaneleke kakhulu yezingxenye zakho zensimbi zangokwezifiso. Kungakhathaliseki ukuthi ubeka phambili ukunemba, ukuphumelela kwezindleko, noma ukuhambisana kwezinto ezibonakalayo, ukuqondanisa ukukhetha kwakho nezidingo zohlelo lwakho lokusebenza kuqinisekisa imiphumela emihle.

Ukukhetha phakathi komshini we-CNC nokusakazwa kwensimbi kudinga ukuqonda umehluko wabo oyinhloko. Imishini ye-CNC inikezela ngokunemba okuphezulu nokuguquguquka, okuyenza ilungele imiklamo eyinkimbinkimbi kanye nokugijima kokukhiqiza okuncane. I-Metal cast, nokho, ihamba phambili ekukhiqizweni kwevolumu ephezulu ngokungabizi kahle kanye nesivinini. Ukuze ukhethe inqubo efanele, cabangela izici ezifana nevolumu yokukhiqiza, izidingo zokunemba, nokuhambisana kwezinto. Ukubonisana nochwepheshe kungakunikeza izeluleko ezihambisanayo, uqinisekise ukuthi inqubo yakho yokukhiqiza ihambisana nezidingo zakho ezithile zephrojekthi. Ngokuhlanganisa izidingo zakho zokukhiqiza ngendlela efanele, uqinisekisa imiphumela emihle yezingxenye zakho zensimbi ezingokwezifiso.